Monitoring the on-farm hatching process through IoT devices and data insights

NestBorn is a revolutionary on-farm hatching concept that significantly improves the level of welfare and health of broilers. We partnered with the NestBorn team to build an IoT-powered monitoring product that measures key data parameters and provides insights and alerts throughout the hatching process; giving farmers greater assurances that there are no anomalies in their production.

Challenge

Prior to our cooperation, the NestBorn team had already created a PoC application with sensors making key measurements during the on-farm hatching process. Our challenge: turn that PoC into a robust digital solution ready for global expansion.

Solution

We architected and built a brand-new software foundation. This wasn't just a rewrite; it was a complete overhaul, designed to handle sensor data from their next-gen hardware, giving field operators real-time insights. We also tackled the challenge of legacy hardware, reverse-engineering it to ensure seamless compatibility and uninterrupted service for their clients.

Approach

We dove deep into the on-farm hatching workflow, understanding the nuances and challenges. We then crafted a completely reimagined user experience through interactive Figma prototypes, visualizing and refining every interaction. We mapped out a modern, cloud-native architecture, laying the groundwork for scalability. Finally, we assembled a dedicated team, focused on delivering a high-quality solution, fast.

Joachim De Backere

Product owner NestBorn

"When working inside farms, there are a ton of environmental parameters to consider for a successful hatching process. We found a knowledgeable and trustworthy partner in Panenco to turn our ideas into reality. Thanks to an effective joint operating model, building the new version of the NestBorn platform went really smoothly."

Shaping a digital solution in support of real-world activities

We were fortunate to have access to extensive field experience, which proved invaluable in defining the functional specifications. The NestBorn team guided us through their on-farm hatching processes, articulating how they envisioned a technological solution to enhance their daily operations.

IoT device research

From the outset, we knew we'd be integrating with existing hardware devices from Petersime, a specialist in hatchery technology. We developed a proof of concept, integrating their Ovoscan IoT solution and channeling the device's raw IoT data into an Influx database.

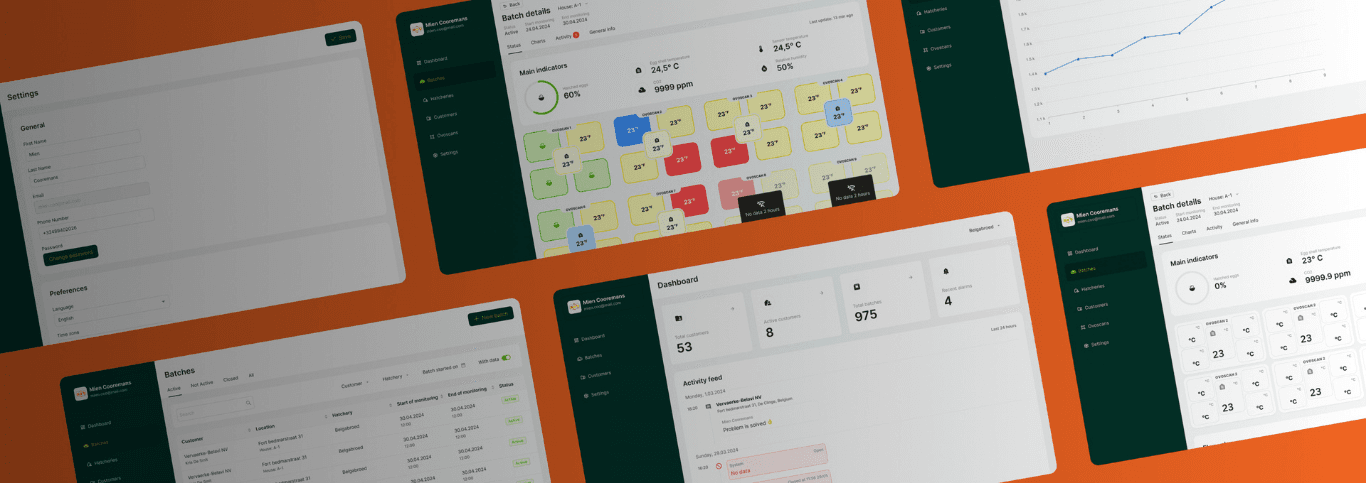

Product design

We meticulously mapped out the end-user journey for field operators deploying NestBorn on client sites, from device installation to configuration and monitoring. Through detailed, interactive prototypes, we ensured all stakeholders were aligned on the product development path.

Building a cloud-native digital infrastructure

We developed a tailored cloud-based product, designed to process sensor data streams and present crucial insights to farmers via a responsive web application.

Technological choices

We implemented a cloud-native architecture using Google Cloud Platform and a time-series database (InfluxDB). The back-end is comprised of Node.js microservices, powering a React.js front-end application. Leveraging containers and serverless components, the system is primed for global scalability.

Dealing with legacy data

We addressed the need to support legacy devices from the previous system. These devices upload files to a bucket, which our microservices then retrieve, parse, and ultimately integrate into Influx, our time-series database.

Hardware-software interaction

Working with the new sensors, Petersime's intuitive API (Eagle Trax) enabled us to retrieve pre-parsed data at regular intervals. This data was then integrated into Influx, mirroring the handling of legacy data. This streamlined process made our integration with Petersime remarkably smooth.

From conceptualisation towards production in under 4 months

Leveraging our existing expertise in developing similar IoT-based solutions, we were able to accelerate the project from the outset. We assembled a dedicated team to construct the product end-to-end, fostering a collaborative environment with our client through shared tools, communication channels, and joint daily stand-up meetings.

Team composition

We advocate for the efficacy of small, focused teams with clear delivery mandate. The NestBorn product team comprised an engineering manager, a front-end engineer, and a back-end engineer, supported by a product designer. This lean team structure ensured minimal overhead and streamlined operational processes.

Operating model

We implemented agile operating routines, adhering to a two-week sprint cycle, incorporating bi-weekly planning sessions, daily stand-up meetings, and comprehensive product demonstrations at the culmination of each sprint. We operated with complete transparency, fostering a genuine co-creation partnership with our client.

"Working on NestBorn was a true joy for us as it resonated with a lot of our prior work for clients like SoundTalks and CHARP, turning IoT sensor data into actionable insights and timely alerts. We wish their entire team the very best of luck as they will be rolling out this solution to clients globally. We'll be happy to keep supporting you every step of the way."

Johan Haest

Engineering manager

Sebastiaan Viaene

Engineering manager